Unbending and re-bending the prongs for use in another application makes them brittle and increases the risk of failure.įor the best results, if you need to replace or remove a cotter pin, discard the old pin and use a new one in its place. However, cotter pins are generally single-use only. Though the materials are soft enough to bend with a pair of pliers, these pins provide a strong, reliable locking mechanism once the prongs are bent into their secured shape.

Whether made from stainless or zinc-plated steel, cotter pins are made to last once installed. Clip any excess length from the end of the pin to prevent snags or jams, but leave enough to prevent slipping through the bolt while machinery is in use. Then, using pliers, secure the cotter pin by spreading the prongs in opposing directions.

6 cotter pins install#

To properly install a cotter pin, insert the pin into the hole of the bolt until the pin’s head is flush against the bolt. You must install cotter pins correctly, especially when used around heavy-duty machinery or in hazardous environments, to prevent operational issues or potential health risks. If you're unsure which type of cotter pin is right for your needs, FMW Fasteners can help you compare the benefits and applications of each material. Stainless steel is often more durable and corrosion-resistant than zinc, but zinc is typically the more cost-effective option. Whether you need zinc-plated or stainless steel pins depends on your project needs and budget. If you can’t find a cotter pin that fits the exact length requirements of your item, choose a larger-sized cotter pin and cut the materials down to the ideal size.

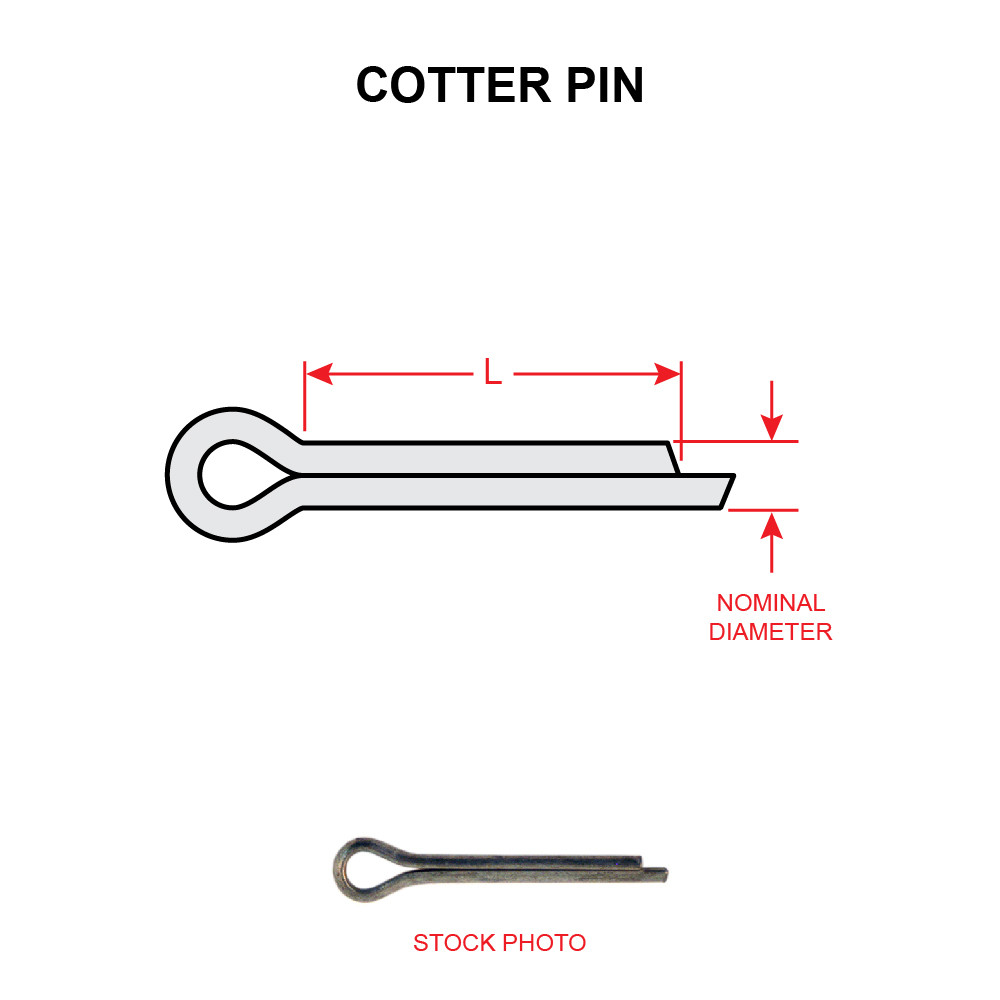

When the prongs of the pin are pulled well apart, they provide a stable hold and won't slip out.Ĭotter pins are ideal for use with bolts intended for machinery that moves or vibrates. Once the pin is all the way through the hole, you twist the ends of the pin outwards so that they pull away from each other. To attach a cotter pin to a compatible bolt, you simply slide it into the hole. Certain types of bolts are specifically designed for use with cotter pins and have pre-drilled holes for this purpose. The primary use for a cotter pin is to secure a bolt by slipping into a hole drilled in the bolt body. There are also different styles of cotter pins available, from extended prong pins to R-shaped pins. These U-shaped pieces of metal with a wide circular top can be made from stainless steel or zinc and come in a range of sizes. What Are Cotter Pins?Ĭotter pins, also known as split pins, are designed to hold bolts in place. When you need cotter pins that are going to work hard each day, just like you do, find the toughest cotter pins available when you choose FMW Fasteners as your supplier. A cotter pin is a two-pronged fastener made from metal that installs easily while providing structural support.įMW Fasteners offers both zinc-plated and stainless steel cotter pins. Cotter pins, while simple in design, are infinitely useful when you need to keep pieces of machinery in place and secure over a period of time.

0 kommentar(er)

0 kommentar(er)